Agate Stripping Guides: A Comprehensive Guide

Agate stripping guides‚ historically crucial for bamboo fly rods‚ represent a blend of artistry and functionality‚ predating modern alloys and chrome-treating techniques;

These guides‚ often sourced from Joe Arguello‚ Hopkins and Holloway‚ or Seymo Jade & Agate‚ showcase meticulous craftsmanship and enduring appeal within the fly fishing community.

Historical Context of Agate Guides

Agate stripping guides emerged as a necessity in the early days of fly fishing‚ specifically with the rise of split-cane bamboo rods. Before the advent of modern materials and surface treatments‚ like chrome‚ the polished agate provided a remarkably smooth and durable surface.

Around a century ago‚ or even earlier‚ these guides weren’t simply functional components; they were a testament to the ingenuity of rod makers. The highly polished stone minimized line wear‚ a critical concern when lines were often made of silk or gut.

Early rod builders recognized the need for a low-friction surface to protect delicate lines and maximize casting distance. Agate‚ with its natural hardness and ability to be polished to a glass-like sheen‚ proved ideal. This period represents a golden age of craftsmanship‚ where the quality of the agate and the skill of the maker were paramount.

The use of agate guides signifies a time when fly rod building was a deeply artisanal pursuit‚ prioritizing longevity and performance through careful material selection and meticulous construction.

Early Manufacturing Techniques

The creation of agate stripping guides in the early days was a labor-intensive process‚ relying heavily on skilled handwork. Initially‚ agate stones were sourced and then carefully cut to the desired size and shape‚ often utilizing diamond-impregnated saws or grinding wheels.

A crucial step involved creating a perfectly circular opening through the agate. This was achieved using specialized drills and abrasive compounds‚ like diamond dust mixed with water‚ to slowly wear away the stone. Maintaining consistent pressure and cooling was vital to prevent cracking.

Simultaneously‚ nickel silver frames and mounts were fabricated‚ often by hand-filing and soldering. These frames were designed to securely hold the agate and attach to the rod blank. The agate was then carefully set into the frame‚ ensuring a snug and precise fit.

Finally‚ extensive polishing was undertaken to achieve the signature smooth‚ glossy finish of the agate‚ maximizing its line-friendly properties. This entire process demanded patience‚ precision‚ and a deep understanding of materials.

The Rise of Modern Alternatives

As materials science advanced‚ alternatives to agate stripping guides began to emerge‚ challenging their long-held dominance. The development of modern alloys and chrome-treating techniques offered manufacturers the ability to create guides with comparable smoothness and durability‚ but at a lower cost and with greater ease of production.

Ceramic guides‚ particularly those made from aluminum oxide or silicon carbide‚ quickly gained popularity. These materials offered excellent wear resistance and reduced friction‚ mimicking the benefits of polished agate. Furthermore‚ plastic and composite guides provided lightweight options‚ appealing to anglers seeking enhanced rod balance.

Despite these advancements‚ agate guides haven’t disappeared entirely. Many traditionalists and bamboo rod enthusiasts continue to prefer the aesthetic appeal and perceived performance benefits of genuine agate.

However‚ the accessibility and affordability of modern alternatives have undeniably shifted the market‚ making them the dominant choice for most contemporary fly rod builds.

Understanding Agate Stripping Guides

Agate stripping guides‚ vital components for bamboo fly rods‚ utilize polished agate rings within nickel silver frames‚ ensuring smooth line flow and minimizing friction.

What are Agate Stripping Guides?

Agate stripping guides are specialized components historically essential for bamboo fly rods‚ though their use extends to other rod materials as well. They function as the first guide positioned after the reel seat‚ managing the line as it travels down the rod during casting.

Unlike conventional guides made from metal or ceramic‚ agate guides feature a ring crafted from polished agate stone. This smooth‚ non-porous surface dramatically reduces friction on the fly line‚ contributing to longer‚ more effortless casts. Before the advent of modern alloys and chrome-treating techniques‚ agate provided a superior solution for line management.

These guides aren’t merely functional; they are often considered aesthetically pleasing‚ adding a touch of classic elegance to a fly rod. The quality of the agate‚ the precision of the cut‚ and the craftsmanship of the surrounding nickel silver frame all contribute to the guide’s overall performance and value. Suppliers like Joe Arguello continue to offer these traditional components to rod builders today.

Materials Used in Agate Guide Construction

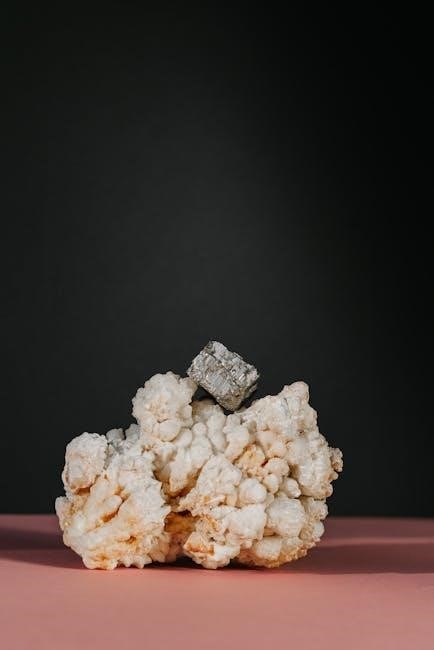

The core component of an agate stripping guide is‚ naturally‚ agate itself. Specific agate varieties are chosen for their hardness‚ smoothness‚ and aesthetic qualities. These stones are carefully cut and polished to create the line-contacting ring.

Complementing the agate is nickel silver‚ a crucial material for the guide’s frame and mounting structure. Nickel silver provides strength‚ corrosion resistance‚ and a suitable metal for shaping into intricate designs. Historically‚ it was favored before modern alloys became prevalent.

The construction also necessitates adhesives like epoxy for secure attachment to the rod blank. Additionally‚ diamond dust‚ functioning as a cutting compound‚ is vital during the agate shaping process‚ ensuring precision and a flawless finish. Finally‚ thread is used for securing the guide‚ often in conjunction with epoxy‚ creating a robust and lasting bond.

Agate Varieties and Their Properties

While the term “agate” encompasses a wide range of chalcedony varieties‚ certain types are preferred for stripping guides. The key property is a fine grain structure‚ ensuring a smooth‚ low-friction surface for the fly line. This minimizes wear and maximizes casting distance.

Brazilian agate is frequently utilized due to its availability and consistent quality. Other varieties‚ exhibiting unique banding or coloration‚ are sought after for aesthetic appeal‚ though performance remains paramount. The hardness of the agate is also critical; it must withstand repeated contact with the fly line without significant abrasion.

The translucency of the agate can vary‚ influencing its visual appearance. Skilled guide makers carefully select stones‚ considering both functional properties and the desired aesthetic outcome‚ creating guides that are both beautiful and effective.

Nickel Silver Frames and Mounts

Nickel silver‚ an alloy of nickel‚ copper‚ and zinc‚ is the traditional material for crafting the frames and mounts that secure the agate stone within a stripping guide. Its selection isn’t based on silver content‚ but rather its corrosion resistance and ability to be readily formed and soldered.

Early rod builders favored nickel silver due to its superior durability compared to other available metals‚ especially before modern alloys and chrome-treating techniques were prevalent. The frames are meticulously shaped to cradle the agate‚ providing a secure and aesthetically pleasing fit.

These mounts are often hand-fabricated‚ requiring skilled craftsmanship to ensure precise dimensions and a robust connection to the rod blank. The quality of the nickel silver and the precision of its construction directly impact the guide’s longevity and performance.

The Manufacturing Process

Agate guide creation involves sourcing‚ cutting‚ and shaping the stone‚ alongside crafting nickel silver frames‚ followed by meticulous polishing and finishing techniques for optimal performance.

Sourcing and Cutting Agate

Sourcing high-quality agate is the foundational step in crafting these specialized guides. Historically‚ and continuing today‚ skilled artisans seek out agate possessing the necessary clarity‚ hardness‚ and desirable banding patterns. The raw agate material often arrives as larger nodules or sections‚ requiring careful assessment to determine the yield of usable stripping guide blanks.

The cutting process itself is a delicate operation. Utilizing diamond-impregnated blades and a precise cutting apparatus‚ the agate is initially shaped into rough preforms. A clay ring‚ filled with water and diamond dust‚ is employed to aid in the cutting and grinding stages. This method ensures a smooth‚ controlled cut‚ minimizing waste and preserving the integrity of the stone. The initial cuts are designed to reveal the most aesthetically pleasing and structurally sound sections of the agate‚ maximizing the visual appeal and functional durability of the final guide.

Careful consideration is given to the orientation of the agate bands during cutting‚ as this impacts the guide’s overall appearance and performance.

Shaping the Agate Stone

Following the initial cutting‚ the agate preforms undergo a meticulous shaping process to achieve the precise dimensions required for a stripping guide. This stage relies heavily on specialized lapidary equipment and the artisan’s skill. Utilizing rotating abrasive wheels and diamond-impregnated compounds‚ the rough agate is gradually refined.

The shaping process isn’t merely about achieving the correct size; it’s about creating a smooth‚ consistent bore – the critical channel through which the fly line will pass. This bore must be perfectly circular and free of any imperfections that could cause friction or line wear. The exterior of the agate is also carefully contoured‚ often with a slight taper‚ to optimize its fit within the nickel silver frame.

Throughout shaping‚ constant inspection is crucial‚ ensuring the agate’s natural beauty and structural integrity are preserved. The goal is a perfectly formed agate ready for polishing and integration into the final guide assembly.

Creating the Nickel Silver Frame

The nickel silver frame‚ essential for securing the agate stone‚ is typically crafted through a combination of machining and hand-fitting. Artisans begin with nickel silver rod or sheet‚ carefully shaping it to the desired dimensions using lathes and milling machines. Precision is paramount‚ as the frame must precisely accommodate the shaped agate.

The frame’s design incorporates features for attaching to the rod blank‚ often involving precisely positioned feet or wire loops. These attachment points are meticulously formed to ensure a secure and durable bond. The frame is then often split‚ allowing for careful insertion of the agate stone‚ followed by silver soldering or brazing to permanently join the two components.

After soldering‚ the frame undergoes filing and smoothing to eliminate any sharp edges or imperfections‚ preparing it for polishing and a seamless integration with the agate.

Polishing and Finishing Techniques

Polishing agate guides is a multi-stage process demanding patience and skill. Initially‚ the nickel silver frame receives meticulous polishing using progressively finer abrasive compounds‚ achieving a brilliant‚ mirror-like sheen. This often involves buffing wheels and specialized polishing pastes.

The agate stone itself undergoes similar treatment‚ starting with coarser grits to remove any remaining imperfections from cutting and shaping. Diamond dust‚ suspended in water‚ is frequently employed for this purpose‚ gradually refining the surface.

As the agate nears its final polish‚ finer compounds are used‚ culminating in a high-luster finish that enhances the stone’s natural beauty. The final step often involves careful cleaning and inspection to ensure a flawless‚ light-transmitting surface‚ ready for installation on a bamboo fly rod.

Installation and Application

Agate stripping guides are primarily utilized on bamboo fly rods‚ requiring careful rod blank preparation and precise attachment using epoxy and traditional threading techniques.

Agate Guides for Bamboo Fly Rods

Agate stripping guides hold a significant place in the history of bamboo fly rod construction‚ representing a time before advanced materials dominated the sport. Their application isn’t merely functional; it’s a nod to tradition and a pursuit of refined aesthetics. These guides were‚ and continue to be‚ favored for their smooth surface‚ minimizing friction on the fly line during casting.

The inherent properties of agate‚ combined with the craftsmanship of nickel silver frames‚ create a guide that complements the natural beauty of bamboo. Installation requires a skilled hand‚ as precise placement is crucial for optimal performance. The guides aren’t simply glued on; they are carefully secured with both epoxy and tightly wrapped thread‚ ensuring durability and a seamless integration with the rod’s overall structure.

Fly fishers often choose agate guides for their classic look and the unique character each stone possesses. They represent a connection to the heritage of fly rod building‚ a testament to the enduring appeal of handcrafted equipment.

Rod Blank Preparation

Preparing the bamboo rod blank for agate stripping guides is a critical step‚ demanding meticulous attention to detail. The blank must be flawlessly smooth and free of any imperfections that could compromise the guide’s adhesion or line flow. This often involves careful planing and sanding‚ ensuring a consistent diameter where the guides will be positioned.

Before applying any adhesive‚ the area for each guide is typically “sized” with multiple coats of varnish or a similar sealant. This process hardens the bamboo fibers‚ creating a more stable and durable surface. A clay ring‚ carefully formed around the blank‚ provides a precise guide placement channel and prevents epoxy from running during installation.

The clay ring must be perfectly aligned and sized to accommodate the agate guide‚ ensuring a snug and secure fit. Proper preparation is paramount‚ as it directly impacts the guide’s longevity and the rod’s overall casting performance.

Attaching the Agate Stripping Guide

With the rod blank meticulously prepared‚ attaching the agate stripping guide requires precision and patience. The guide is carefully positioned within the clay ring‚ ensuring proper alignment along the rod’s spine. A high-quality epoxy is then applied‚ generously filling the space between the agate and the bamboo.

The epoxy must fully encapsulate the guide’s frame and the agate stone itself‚ creating a robust bond. During this process‚ it’s vital to prevent air bubbles from forming‚ as they can weaken the connection. Gentle manipulation and tapping can help release trapped air.

Once the epoxy is applied‚ the rod is left to cure‚ typically for 24-48 hours‚ depending on the epoxy’s specifications. After curing‚ the clay ring is carefully removed‚ revealing a securely mounted agate stripping guide‚ ready for finishing touches.

Epoxy and Threading Techniques

Epoxy plays a critical role in securing agate stripping guides‚ demanding careful application to ensure a lasting bond. Modern rod builders favor slow-curing epoxies‚ allowing ample working time and minimizing air bubble formation around the agate and nickel silver frame.

While traditionally‚ guides were solely epoxy-mounted‚ some builders incorporate thread wraps for added security and aesthetic appeal. This involves tightly wrapping silk or nylon thread around the guide’s frame before epoxy application‚ creating a mechanical lock.

The epoxy is then applied in multiple thin coats‚ building up a smooth‚ even finish. Proper mixing ratios are crucial for optimal curing and strength. After each coat‚ the epoxy is allowed to partially set before applying the next‚ preventing runs and ensuring a durable‚ professional result.

Maintenance and Repair

Agate stripping guides require gentle cleaning with water to preserve their polish. Cracked or chipped agate may necessitate professional repair or replacement‚ alongside damaged frames.

Cleaning Agate Guides

Agate stripping guides‚ prized for their smooth surfaces‚ demand careful cleaning to maintain optimal performance and aesthetic appeal. Regular cleaning prevents the buildup of grime‚ fly line residue‚ and other contaminants that can impede line flow and diminish casting accuracy.

The recommended cleaning method involves gently washing the guides with lukewarm water and a mild soap. Avoid abrasive cleaners or harsh chemicals‚ as these can scratch or dull the polished agate surface. A soft-bristled brush‚ like an old toothbrush‚ can be used to dislodge stubborn debris from the frame and the inner diameter of the guide.

Rinse the guides thoroughly with clean water and dry them with a soft cloth. It’s crucial to ensure all soap residue is removed‚ as any remaining soap can attract dirt and affect the guide’s performance. Periodic cleaning‚ especially after frequent use in saltwater environments‚ will significantly extend the lifespan and maintain the integrity of your valuable agate stripping guides.

Repairing Cracked or Chipped Agate

Agate stripping guides‚ despite their durability‚ can occasionally suffer cracks or chips‚ particularly with accidental impacts. Repairing these imperfections requires a delicate approach to preserve the guide’s functionality and value. Minor chips can sometimes be polished smooth using progressively finer grades of diamond polishing compound and a lapidary polishing wheel‚ restoring a smoother surface for line passage.

However‚ significant cracks often necessitate professional repair or replacement. Attempting to glue a severely cracked agate stone can compromise its structural integrity and potentially lead to further damage during use. Skilled artisans specializing in agate restoration can carefully rebuff and repolish damaged areas‚ or even replace the agate stone entirely.

Preventative measures‚ such as careful handling during rod assembly and storage‚ are crucial. If a guide is beyond repair‚ sourcing a replacement from reputable suppliers like Joe Arguello or Hopkins and Holloway ensures continued performance and maintains the classic aesthetic of your bamboo fly rod.

Replacing Damaged Frames

Nickel silver frames‚ while robust‚ can become bent‚ corroded‚ or otherwise damaged on agate stripping guides. Replacing a damaged frame requires careful disassembly and a degree of silversmithing skill. Gently remove the old frame‚ taking care not to further damage the agate stone itself. Accurate measurements are crucial for crafting a new frame that perfectly fits both the agate and the rod blank.

Creating a replacement often involves forming nickel silver wire to the correct shape‚ soldering the joints securely‚ and then carefully fitting the agate stone into the new frame. Polishing the frame to a bright finish completes the process‚ restoring the guide’s original appearance.

Alternatively‚ pre-made frames can be sourced from specialized suppliers. When replacing frames‚ ensure the new frame’s dimensions precisely match the original to maintain proper line control and prevent unnecessary stress on the rod.

Modern Suppliers and Resources

Joe Arguello‚ Hopkins and Holloway‚ and Seymo Jade & Agate Stripping Guides remain key sources for authentic agate components and expertly crafted guides today.

Joe Arguello’s Agate Guides

Joe Arguello is a highly respected name among bamboo fly rod builders‚ renowned for supplying high-quality agate stripping guides. He provides both 9mm and 10mm sizes‚ catering to a variety of rod builds and preferences.

Arguello’s guides are particularly favored for their consistent quality and suitability for classic bamboo rods. His offerings represent a direct link to traditional fly rod making practices‚ providing builders with authentic materials.

Many builders specifically seek out Arguello’s guides for restoration projects‚ ensuring a faithful reproduction of the original components. His commitment to providing genuine agate and well-crafted guides has established him as a trusted resource within the community. He is a go-to source for those seeking to maintain the integrity and beauty of vintage bamboo fly rods.

Sourcing from Joe Arguello ensures builders receive guides that meet the exacting standards required for both performance and aesthetic appeal.

Hopkins and Holloway

Hopkins and Holloway are established suppliers of agate stripping guides‚ catering to the needs of fly rod builders and restorers. They offer a selection of these classic components‚ maintaining a tradition of quality craftsmanship.

The company provides a valuable resource for those seeking authentic materials for bamboo fly rod construction and repair. Their guides are known for their precision and suitability for traditional builds‚ appealing to enthusiasts who value historical accuracy.

Hopkins and Holloway’s offerings contribute to the preservation of classic fly fishing techniques and aesthetics; They are a reliable source for builders looking to replicate the original specifications of vintage rods‚ ensuring a faithful restoration.

Their commitment to supplying genuine agate guides supports the continued practice of this time-honored craft‚ providing essential components for both novice and experienced rod builders.

Seymo Jade & Agate Stripping Guides

Seymo Jade & Agate Stripping Guides‚ offered by Seymo‚ represent a continuing source for these traditional components within the fly fishing community. Seymo provides a range of agate guides‚ catering to both restoration projects and new bamboo rod builds.

The company’s offerings are frequently mentioned alongside other reputable suppliers like Hopkins and Holloway and Joe Arguello‚ indicating a recognized presence in the market for classic fly rod materials. Seymo’s guides contribute to the availability of authentic components.

Fly fishers seeking to maintain the integrity of vintage rods or replicate the aesthetics of classic builds often turn to Seymo for their agate stripping guide needs. Their products support the preservation of traditional fly fishing techniques.

Seymo’s dedication to supplying quality agate guides ensures that builders have access to essential materials for creating and restoring beautiful‚ functional bamboo fly rods.

Advanced Techniques and Considerations

Agate guide placement impacts casting‚ while custom designs enhance performance. Optimizing guide size is crucial‚ demanding skilled craftsmanship for perfect integration with rod blanks.

Custom Agate Guide Design

Crafting bespoke agate stripping guides transcends simple component selection; it’s an exercise in artistic expression and performance optimization. Historically‚ guides were “standard‚” but modern rod builders increasingly seek unique aesthetics and tailored functionality.

The process begins with carefully sourced agate‚ chosen not only for its visual appeal – banding‚ color‚ and clarity – but also for its inherent structural integrity. Custom designs often involve specifying the agate’s cut and shape‚ moving beyond traditional ring forms.

Nickel silver frames are then meticulously fabricated to complement the stone‚ with variations in wire gauge‚ foot style‚ and overall profile. Builders may request specific embellishments or engravings on the frame‚ further personalizing the guide.

Considerations extend to the guide’s internal diameter‚ influencing line flow‚ and its external dimensions‚ ensuring a harmonious fit with the rod’s taper. Ultimately‚ a custom agate guide is a testament to the builder’s vision and dedication to creating a truly exceptional fly rod.

Optimizing Guide Placement for Performance

Strategic placement of agate stripping guides is paramount to a bamboo fly rod’s casting performance and overall feel. Unlike modern guides‚ agate guides demand precise positioning due to their inherent weight and influence on rod flex.

Traditionally‚ the first guide is positioned slightly further up the rod than with contemporary setups‚ accounting for the agate’s mass. Subsequent guides follow a carefully calculated spiral‚ minimizing line friction and ensuring smooth power transfer during the cast.

Guide spacing isn’t uniform; it’s adjusted based on the rod’s taper and intended line weight. Closer spacing near the handle helps control the bend‚ while wider spacing towards the tip promotes smoother line release.

Experienced builders consider the rod’s action – fast‚ medium‚ or slow – when determining optimal placement. A poorly placed agate guide can introduce unwanted torque or hinder casting distance‚ highlighting the importance of meticulous attention to detail.

The Impact of Guide Size on Casting

Agate stripping guide size significantly influences casting performance‚ dictating line flow and overall rod balance. Commonly‚ sizes range from 8mm to 10mm‚ with selection dependent on the rod’s intended line weight and taper.

Smaller guides (8mm) are generally suited for lighter line weights and delicate presentations‚ minimizing line contact and preserving sensitivity. Larger guides (10mm) accommodate heavier lines and provide smoother line flow during powerful casts‚ reducing friction.

Incorrect guide size can lead to several issues; An undersized guide restricts line movement‚ increasing friction and potentially damaging the line. Conversely‚ an oversized guide adds unnecessary weight and can disrupt the rod’s natural bend.

Builders often match guide size to the rod’s butt diameter‚ ensuring a visually appealing and functionally sound setup. Careful consideration of these factors is crucial for maximizing casting efficiency and achieving optimal performance with agate stripping guides.